The mould tool concept of the future

Automated production process – sustainable and energy-efficient

A look into the future shows that future automation in plastics processing is inevitable. Future-oriented tool concepts must therefore be suitable especially for automated production processes.

IsoForm® moulding tools meet this requirement because they can reach the process temperature energy-efficiently, sustainably and quickly.

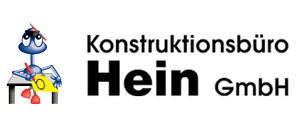

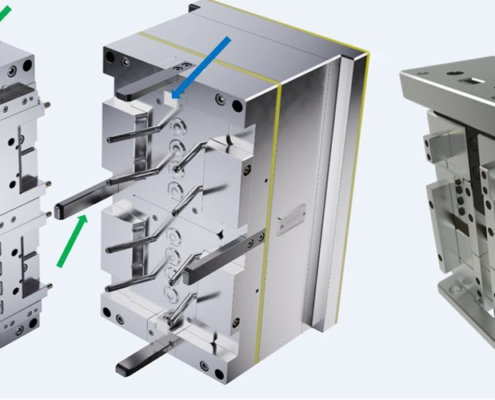

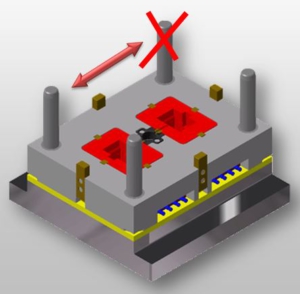

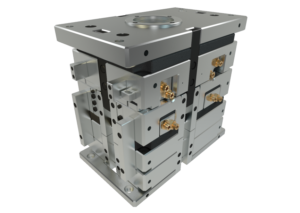

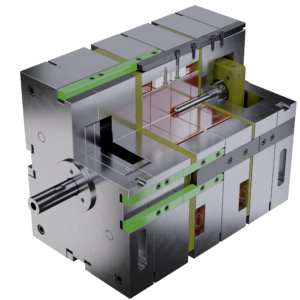

Central centering and ejector system

centring

- consistent hub-centring of the inserts, mould plates and mould halves to each other

- high precision

- different thermal expansion is compensated

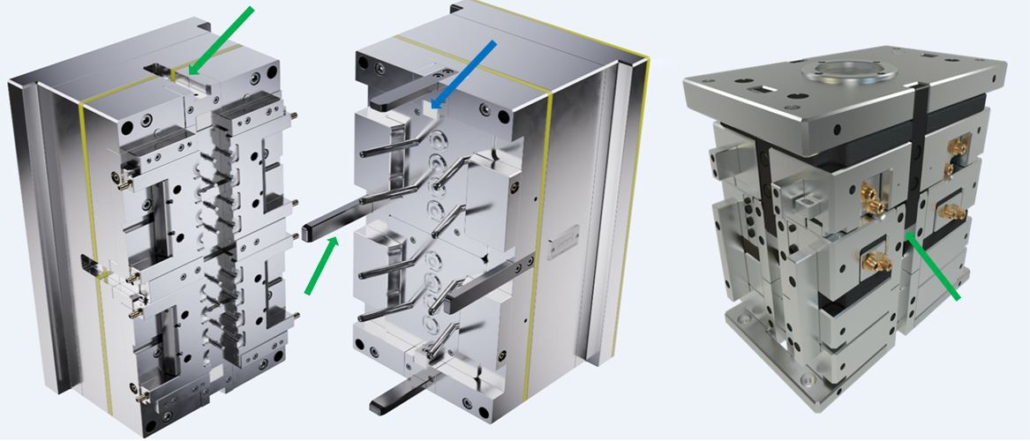

Centering is carried out for the mould inserts with ceramic elements (2W/mK, blue arrow, fig. middle), which serve as the only connection between the “hot” mould insert and the mould carrier frame also for thermal separation.

Hub-centring between mould plates (green arrows, fig. left) allows for adapting temperature regulation to different requirements and for a simple, fast and precise mounting and dismounting of the tool.

The central centring also over the plates of the mould assembly (green arrow, fig. right) enables the temperature control to be adjusted as required, as well as simple, fast and precise assembly and disassembly of the mould.

ejection system

- function-oriented ejector plate system

- maximum passive support

- long tool life

- low deflection

- avoidance of burr formation

Why do I need IsoForm® and what are the advantages?

In addition to increased process reliability, the consistent thermal insulation of the contour area offers enormous advantages in terms of time and energy requirements:

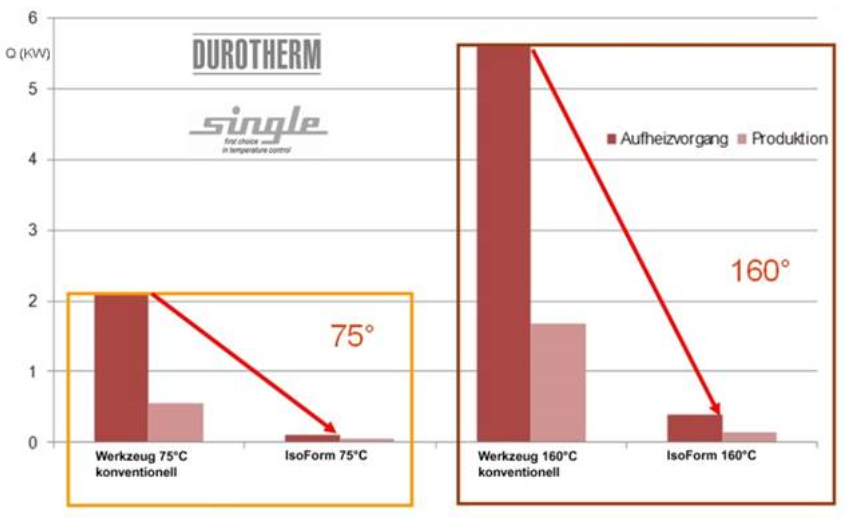

The sustainable and extremely efficient tools require up to 95% less energy to heat up for this application compared to conventional tools.

The energy input for heating up a mould for the high temperature range (e.g. PEEK / rubber / silicone / thermosets) is reduced to the same extent.

Worksheet Single/Durotherm – For a premium test tool

Advantages at a glance

- consistent isolation of contour-forming parts against the surrounding mould

- reduced deflection – less to no burr formation

- shorter set-up times, heating phases

- consistent hub-centering >> reduced offset of mould

- perfect as base / principal mould, as exchangeable tool remaining on the machine

- additional isolation of hot runner available (minimizes heating requirements)”

- ideal for cycle-dependent temperature control

- Reduction of energy costs, especially for high-temperature applications

Comparison of the heating phase at 75°C and at 160°C

The illustrated application shows in practice that it is not only possible to reach process temperature with a fraction of the energy required, but also that this goal can be achieved here in 1/5 to 1/10 of the time compared to a conventional tool.

- For elastomers, thermoplastics, thermosets and die-casting

- Higher process reliability, because design and conception exclude sources of error

- Available in all sizes – with IsoForm® advantages

- Clamping fixtures according to usual standard possible

- IsoForm®-BASIC largely costs the same as conventional mould units – with more advantages

- BASIC version can be upgraded with ceramic centering elements at any time

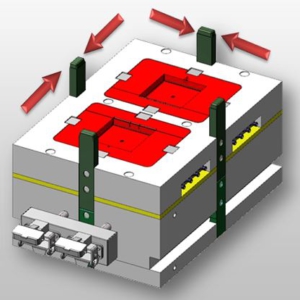

Mould tool changing system

IsoForm®: Different linear expansion has no effect on the centring elements. In this way an exact fit is possible.

Moulding tool changing system

Different linear expansion between injection side and clamping side at different flow temperatures.

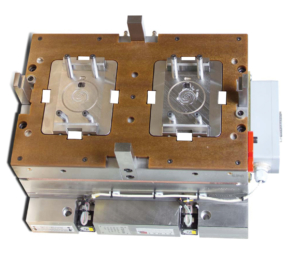

IsoForm® moulding tool changing systems

changing systems

- all IsoForm® advantages

- multiple use of the of the principal mould » favourable proportional tool prices

- Fast, easy change of the production of different components

In the IsoForm® range there are standard mould variants for multiple use, in which the inserts or entire mould plates (also with slides and/or ejectors) can be changed from the parting line. In this way you achieve a fast thermally separated tool change with precise hub-centering, without leaks and difficulties, if necessary with transponders and fully automatic.

This means that the investment in the modular principal mould can be added to the costs for the machine which leads to lower costs for the tool.

Interchangeable mould inserts

- only mould insert with ejector plate is changed

- for small projected areas

- fitting panel for exchange and for protecting the contour

- with screws or locking bars for manual change

- also available for automated change

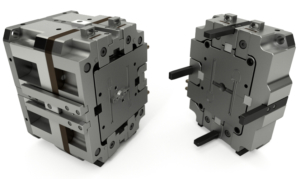

Insert chainging system

Insert chainging system

plate changing system

exchangable plates:

- exchange of the mould plates

- for larger projected areas

- contour areas are protected with cover plates

- reduced storage requirements

- high process reliability and precise centering

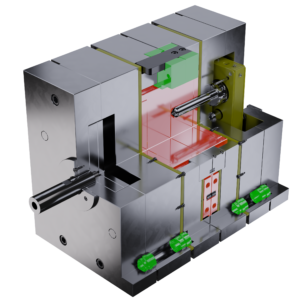

Changing systems:

- with sliders

- with core pins for sleeve ejector

- multiple applications in one tool

- energy efficient and sustainable

- fast and process reliable in production

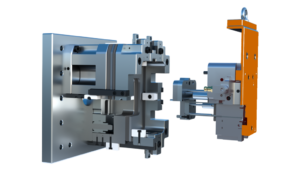

IsoForm® for thermoplastics

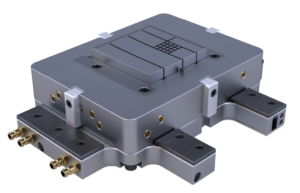

Temparature control

The temperature control of the tools may be individually adapted so that you may use water on one side and a coolant on the other (fig. Right: blue arrow), while connecting sensors and/or gas injection devices on the opposite side.

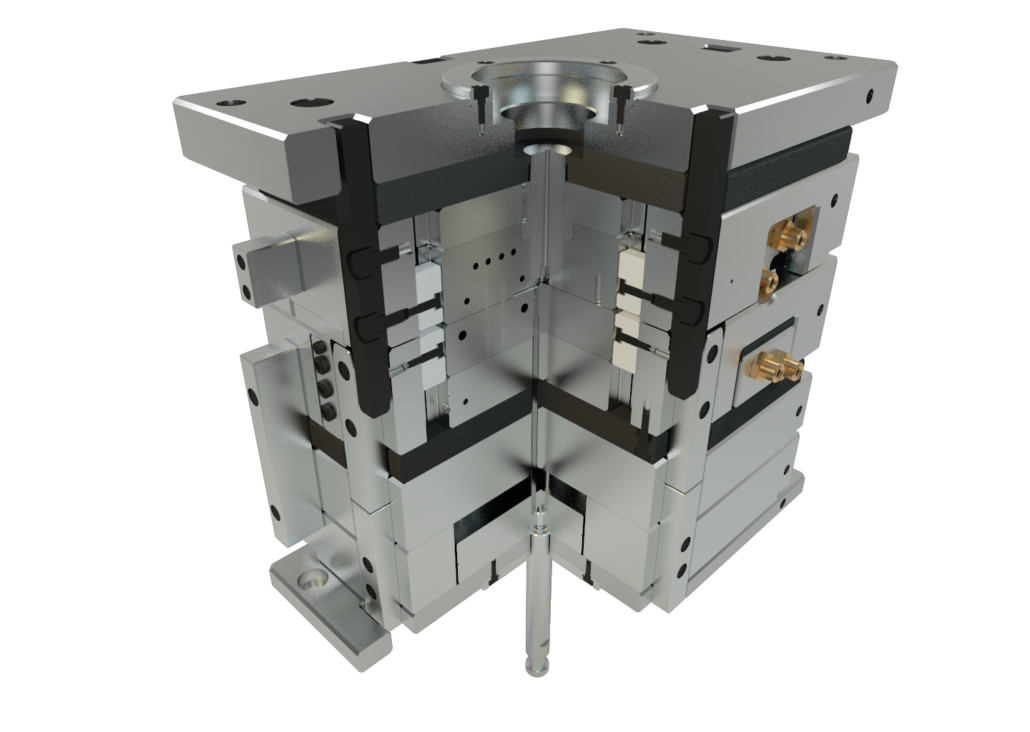

IsoForm® mould tool

- thermal separation

- Hub-centring

- individual temperature control

- moulds in any size

- slides and isolated hot runner

Slide tool

Slide moulds make up the majority of the IsoForm® injection moulds realised. A special feature is the consistently centred guidance of all slides corresponding to the hub-centring of any IsoForm® tool

Another feature is the isolation of the slide and from the mould support frame which we already know from the isolated mould inserts.Thrust pads assist in fine-tuning the mould tool

IsoForm® for thermoplastics

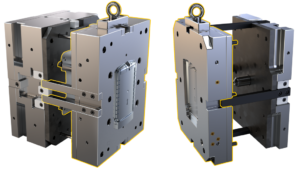

IsoForm® for rubber, silicone and duroplastics

For the processing of cross-linking materials, the thermal separation between the cold area of the material feed and the heated contour area is of elementary importance.

With IsoForm® you can use water to temper up to 240°C (up to 180°C even cycle-dependent). Cycle-dependent temperature control prevents “scorching” in the cavity during filling. The cross-linking can then be started intentionally at the right time.

Silicone:

The example on the right shows the implementation of an application for processing silicone by the tool manufacturer Heite & Krause GbR.

The slides were integrated into the isolated mould insert. Thermal insulation plates in the separation area provide protection against contact.

Ceramic centring elements of the mould inserts ensures that the inserts are fixed in place and the outside lug centrings elements guarantee that areas with neccessarily different temperature regulation don‘t affect the functionality of the entire tool